QUICK LINKS

QUICK LINKS-

Download Brochure

Download Brochure -

About Aluminium Panels

About Aluminium Panels  Send Enquiry

Send Enquiry

Products >> PVDF Aluminium Composite Panel

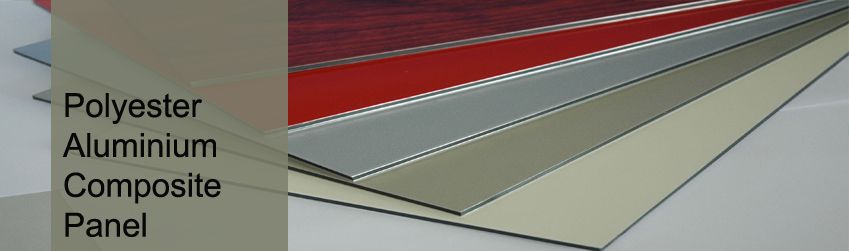

ALSTROM PVDF aluminium composite panel consists of a polyethylene core sandwiched between two 0.5mm aluminium skins. As its name suggests, the ACP is coated with PVDF Kynar 500 / HYLAR 5000 fluorocarbon coating in order to provide a long lasting, durable finish.

PVDF aluminium composite panel advantages and characteristics

- -Superior weather, corrosion, pollutant resistance

- -Excellent sound, heat insulation

- -Superior impact and peel strength

- -Excellent surface flatness and smoothness

- -Light weight and easy to maintain

ALSTROM PVDF aluminium composite panel is ideal to be used for office buildings, shopping centres, industrial buildings, airports, hotels, bus stations, hospitals, schools, supermarkets, and residential buildings.

Technical data of PVDF Aluminium composite panel

| Thickness of coating | PVDF paint ≧25 um | 26um to 28um |

| Coating Flexibility (T-bend) | PVDF paint≦2T | 2T |

| Coating Adhesion | ≧1 grade for 10*10mm2 gridding test | 1 grade |

| Pencil Hardness | ≧HB | HB |

| Resist Solvent | No change for 200 times (MEK) | No change |

| Chemical Resistance | 5%HCL or 5%NAOH-No change for 24hours | No change |

| Boiling Water Resistance | coating no tear off for 2 hours boiling | no tear off |

| Color difference | △E≦2.0(follow color sample) | 0.5 |

| Panel Peeling Strength | 7 N/mm for 4mm panel with 0.5mm aluminium. skin | 7N/mm |

| Impact Test for paint | 50Kg.cm impact--paint no split for panel | no split |

| Abrasion Resistance(L/Mil) | ASTM D968 | 44 |

| Chemical Resistance | ASTM D1308 | Appearance: No change |

| Film Adhesion | ASTM D3359(Note 1) | 5B |

| Detergent Resistance(3%) | ASTM D2248 | Appearance: No change |

| Stripping Strength(kgf/inch) | ASTM D903 | 18.5 |

| Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | Appearance: No change |

| Salt Spray Resistance (3000hrs,5% salt) | ASTM B117 | Appearance: No change |

<<<< Back to products